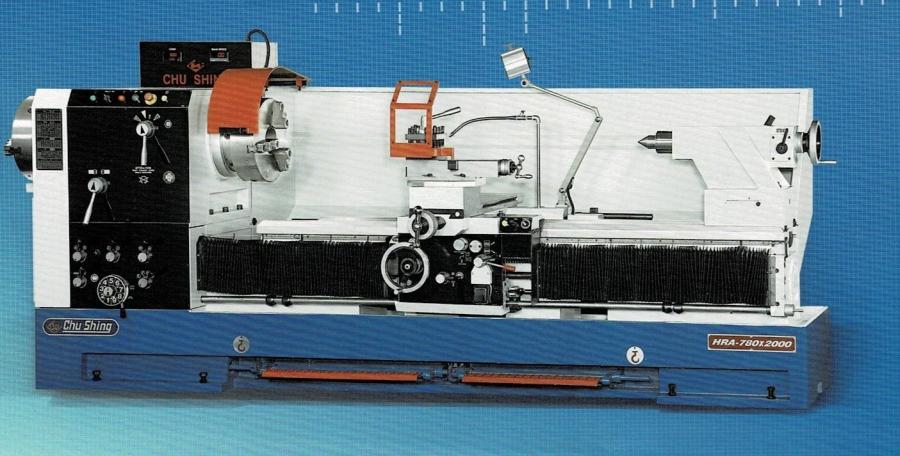

STANDARD ACCESSORIES

Fixed center MT#6

Tool box with tool kits

Pad

Work Light

OPTIONAL ACCESSORIES

Chuck (3-jaw / 4-jaw)

Rotation center MT#6

Face plate

CE device

Follow rest

DRO

Full length splash guard

Steady rest

Category (311)

FEATURES

1. The column, base table, and saddle are constructed for meehanite cast irons.

2. Box type column and base construction combined with rib reinforced for maximum rigidity and outstanding vibration absorbing capability.

3. 3-axis is linear ways.

4. High precision ball screws X, Y, Z-axis, which are directly driven by servo motor without transmission backlash problem.

5. Z axis with brake servo motor & no counter weight which design provide to ensure the best surface accuracy in the 3D machining.

EATURES:

1. TWO HAND WHEEL: The X axis is designed two handle wheel for easy operation.

2. COLUMN: The bed and column are designed as box type with rigid structures. All the main components are made of FC-30 high quality casting and annealing heat treatment.

3. SADDLE: The saddles are designed with wide type for accuracy movement in all direction. The sliding surfaces are coated with turcite-B to ensure smooth and accuracy movement in long time.

4. BALL SCREW: Ball screw for 3-axis will increase work efficiency.

5. LUBRICATION: The automatic lubrication system with pressure gage, adjustable the timing and flow to provide the excellent lubrication oil onto all the sliding ways.

FEATURES:

1. Double nut-precision ball screw for X, Y and Z-axis. It keeps high precision and durability life of machine.

2. X, Y, Z axis employ DC servo motors, providing variable feed speed change. Rapid feed rate provides2-3 times higher efficiency than frequency inverter controlled motor. Greater torque output at low speed running. It can be fitted with optional MPG hand wheel.

3. The automatic lubrication system with adjustable the timing and flow to provide the excellent lubricating oil onto all the sliding ways. When lubricant reaches control-limited, it is ringing and to remind you to fill oil.

4. Spindle head can change to variable head.

5. Spindle nose of spindle head can change to NT50#.

6. Available to equip with H type powerful horizontal cutting mechanism. Featuring gear head drive, servo motor drive on vertical feed and hand wheel control for added operational convenience.

FEATURES:

1. Double nut-precision ball screw for X, Y and Z-axis. It keeps high precision and durability life of machine.

2. X, Y, Z axis employ DC servo motors, providing variable feed speed change. Rapid feed rate provides2-3 times higher efficiency than frequency inverter controlled motor. Greater torque output at low speed running. It can be fitted with optional MPG hand wheel.

3. The automatic lubrication system with adjustable the timing and flow to provide the excellent lubricating oil onto all the sliding ways. When lubricant reaches control-limited, it is ringing and to remind you to fill oil.

4. The VF type head provides 3-step speed change combined with inverter controlled spindle. The spindle speeds are properly arranged, permitting for heavy duty machining and high speed machining.

5. Spindle nose of gears milling head can change to NT50# 3-step.

6. Available to equip with H type powerful horizontal cutting mechanism. Featuring gear head drive, servo motor drive on vertical feed and hand wheel control for added operational convenience.

FEATURES:

1. Double nut-precision ball screw for X, Y and Z-axis. It keeps high precision and durability life of machine.

2. X, Y, Z axis employ DC servo motors, providing variable feed speed change. Rapid feed rate provides2-3 times higher efficiency than frequency inverter controlled motor. Greater torque output at low speed running. It can be fitted with optional MPG hand wheel.

3. The automatic lubrication system with adjustable the timing and flow to provide the excellent lubricating oil onto all the sliding ways. When lubricant reaches control-limited, it is ringing and to remind you to fill oil.

4. Spindle head of G model is NT50# with 6 speed gear shifting and 12 types of speed, which is suitable for rigidity heavy duty cutting.

5. Available to equip with H type powerful horizontal cutting mechanism. Featuring gear head drive, servo motor drive on vertical feed and hand wheel control for added operational convenience.

FEATURES:

1. The bed is adopted hi-rigidity rib structure design & coupled with hi-tensile meehanite cast-iron which is annealed treatment to eliminate internal residual stress, the bed way is high frequency heat treated, precision ground etc.,

2. Three-point support on the spindle and inspected by dynamic balancing, the spindle gear is module 3 & wide, this is very suitable to do heavy duty cutting and being with 3-step speed shifting. Especially, that can output by full power even as the spindle speed at low gear, large cutting force.

3. The carriage is coated with Turcite-B which provides low friction & vibration and ensures smooth movement & accuracy.

4. Adopted central lubrication system which can be lubricated slide way & ball screw. The headstock is adopted forced lubricating & oil bathed combined.

5. Manual tailstock coupled with 1:1 & 1/4:1 feed shifting.

6. The visual window of sliding safety door is adopted the reinforced glass at inner layer and the out layer is polycarbonate, this device can be protected the failure workpieces and be hi-safety.

FEATURES:

1. The spindle headstock: Equipped 3-step gear change (hyd. System) Spindle bore: φ130mm, φ160mm, φ180mm, φ255mm, φ305mm.

2. Dovetail type guide way design for X axis, it can be maximized the swing over cross-slide diameter.

3. Manual tailstock, quill dia. φ165mm, MT6 for center taper and the manual tailstock lubrication system are all standard.

FEATURES:

1. The spindle headstock: 3-point support design for the spindle, and 4-step gear change (hyd. System). Main spindle gear driven is M6 spiral gear.

2. The high rigidity square way design for the X axis, and it can minimized the distortion which is caused by the overhang of slide cover.

3. The tailstock and quill are compacted with fully hydraulic operation. (The tailstock body forward and backward, clamp and unclamp, quill extend and retract) The quill diameter isφ250mm (9.842”) and it is rotatable. The center taper MT6 is standard. And the manual tailstock lubrication is standard.

4. Floor type bed, 3V guide way design, the Z axis ball screw is mounted at front side of the bed. The optional of the second Z axis ball screw can be mounted at the rear side of the bed. The main feature is to reduce the displacement of cross slide.

FEATURES:

1. The column, base table, and saddle are constructed for meehanite cast irons.

2. Box type column and base construction combined with rib reinforced for maximum rigidity and outstanding vibration absorbing capability.

3. 3-axis is linear ways, three linear guide way for Y axis (VMC-1300 / 1500 series)

4. High precision ball screws X, Y, Z-axis, which are directly driven by servo motor without transmission backlash problem.

5. Z axis with brake servo motor & no counter weight which design provide to ensure the best surface accuracy in the 3D machining.

FEATURES:

1. Hi-rigidity machine structure designs and the main casting is made of meehanite cast iron which is annealed perfectly to eliminate internal residual stress.

2. Y, Z axis square rigid ways and dovetail slideway for saddle (X axis), furthermore, the all slideway be treated heat-treatment & precisely ground & scrapped etc.

3. Rugged stand & boxed structure column and integral heavy duty bed type designs and coupled reinforced ribs, advance machining servicing life & accuracy.

4. The spindle is made of SCM-21 steel and tempered stress relieved, carburized & precisely ground etc., and then, equipped with P4 level bearings, hi-precision.

FEATURES:

1. Hi-rigidity machine structure designs and the main casting is made of meehanite cast iron which is annealed perfectly to eliminate internal residual stress.

2. Y, Z axis square rigid ways and dovetail slideway for saddle (X axis), furthermore, the all slideway be treated heat-treatment & precisely ground & scrapped etc.

3. Rugged stand & boxed structure column and integral heavy duty bed type designs and coupled reinforced ribs, advance machining servicing life & accuracy.

4. The spindle is made of SCM-21 steel and tempered stress relieved, carburized & precisely ground etc., and then, equipped with P4 level bearings, hi-precision.